Catalog

Wide Selection — available in a wide variety of body materials, linings and end connections. By utilizing such highly resistant linings as Saran, Polypropylene, Kynar, Tefzel, Glass, Rubber, etc., virtually any chemical service within the pressure/temperature limits of the valve can be handled safely and economically.

No Stem Leakage — since the diaphragm isolates the fluid stream there is no need for a packing gland — no atmospheric contamination, no leakage or waste, no expensive maintenance of stem, seats or stuffing box.

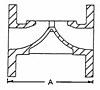

Bubble-Tight Shut Off — results when the downward thrust of the stem and compressor assembly molds the flexible diaphragm against the weir. The diaphragm will accommodate itself to rust, scale, slurry, or fibrous material.

Streamline Flow — with minimum pressure drop because of the absence of grooves, pockets or sharp changes in direction of flow.

Cost Saving — simple in-line maintenance. In less time than it takes to remove and replace a conventional valve, a new body diaphragm can be installed. Thus providing essentially a brand new valve at a tiny faction of the cost of a new or repaired conventional valve — all without removing the valve body from the line.

Flow Control — the automated diaphragm valve provides an excellent means of handling the changing flow requirements in most process installations. By the addition of a positioner to the actuator, even more precise control can be achieved, especially in the handling of slurries, or viscous and fibrous materials.

Body Materials — available in cast iron, ductile iron, carbon steel, stainless steel, Alloy-20, aluminum and bronze

No Stem Leakage — since the diaphragm isolates the fluid stream there is no need for a packing gland — no atmospheric contamination, no leakage or waste, no expensive maintenance of stem, seats or stuffing box.

Bubble-Tight Shut Off — results when the downward thrust of the stem and compressor assembly molds the flexible diaphragm against the weir. The diaphragm will accommodate itself to rust, scale, slurry, or fibrous material.

Streamline Flow — with minimum pressure drop because of the absence of grooves, pockets or sharp changes in direction of flow.

Cost Saving — simple in-line maintenance. In less time than it takes to remove and replace a conventional valve, a new body diaphragm can be installed. Thus providing essentially a brand new valve at a tiny faction of the cost of a new or repaired conventional valve — all without removing the valve body from the line.

Flow Control — the automated diaphragm valve provides an excellent means of handling the changing flow requirements in most process installations. By the addition of a positioner to the actuator, even more precise control can be achieved, especially in the handling of slurries, or viscous and fibrous materials.

Body Materials — available in cast iron, ductile iron, carbon steel, stainless steel, Alloy-20, aluminum and bronze

Unit of Measure

Specifications

Body Material |

N/A Cast Iron |

Temperature Range |

N/A -30 to 300 ºF |

Typical Applications |

N/A Maximum resistance to aggressive chemicals and solvents at elevated temperatures. Excellent anti-stick properties. |

Lining Options |

N/A Unlined |

Material/Lining Classification |

N/A Metal Unlined |

End Connection |

N/A

(1) Flanged Unlined Ends |

End to End Dimension A |

N/A 20 1/2 in |

Valve Size [Fraction] |

N/A 8 in |

Valve Size [Decimal] |

N/A 8.00 in203.20 mm |

Diaphragm Control Valve Options |

N/A

730-RV, Pilot Operated Controller Option |

| Line Pressure Conditions1 | N/A 0% P.D 100% P.D. |

Services |

N/A Acetone Alcohol, Butyl Alcohol, Ethyl Alcohol, Furfuryl Alcohol, Isopropyl Alcohol, Methyl Ammonia, Aqu. Ammonium Nitrate Analine Aromatic Solvents Benzene Black Liquor Brine (Alkaline) Cad. Plating Sol. Cane Sugar - Sol. Casein Water Paint Chlorinated Hydrocarb. Green Liquor Methyl Isobutyl Ketone Methylethyi Ketone Paint Thinner Perchlorethylene Propylene Glycol Tall Oil Toluene - Dry Gas Trichioro-ethylene Tung Oil Turpentine Vacuum to 25 mm. Hg. Varnish White Liquor |

Weight |

N/A 354 lb |

Diaphragm Selection

Diaphragm Material |

N/A PTFE Faced |

Diaphragm Material Description |

N/A TFE PTFE - over the years, a broad range of elastomeric and plastic diaphragms have been developed which will successfully handle all aggressive fluids, gases and slurries, as well as food, beverage and pharmaceutical products where F.D.A. approval of materials of construction is required. The TFE faced diaphragm is backed with fabric reinforced elastomer to provide the high chemical and temperature resistant qualities of TFE with flexibility for longer life and tighter shut-off. |

Standard Actuator Features

Actuator Size Number |

N/A

0, Actuator Size "0" 1, Actuator Size "1" 2, Actuator Size "2" 2A, Actuator Size "2A" 3, Actuator Size "3" 4, Actuator Size "4" 5, Actuator Size "5" |

| Action of Actuator2 |

N/A

(TYPE C) Air to Open - Air to Close  (TYPE H) Spring to Open - Air to Close  (TYPE HRT) Spring to Close - Air to Open |

-

1 100% P.D. means that downstream pressure falls to 0 psig.

0% P.D. means that downstream pressure remains at, or returns to essentially the same as the upstream pressure. -

2 The choice of actuator size is determined by the line pressure through the value and the available operating air pressure. Some operating conditions call for substantial line pressure downstream when the valve closes.

After the valve closes, if the downstream pressure is less that 30 % of the upstream pressure - this condition is 100% Δ P. If the downstream pressure is 30% or more of the upstream pressure - the condition is 0% Δ P.